From DIY cheese producers to boutique cheese factory: Wild Bush Cheese’s success with sheep feta and pecorino

Kirsty Silvester and Dave Chapman are true DIY cheese producers, from pasture to pecorino.

Words and Images: Barbara Gillham & Nadene Hall

Who: Kirsty Silvester & Dave Chapman

What: Wild Bush Cheese

Where: Woodville, 32km east of Palmerston North

Land: 7.2ha (18 acres)

Livestock: Romney, East Friesian, Poll Dorset sheep

Web

Kirsty and friend.

No-one loves Kirsty Silvester’s artisan cheeses more than her mum. The day Wild Bush Cheese got the official tick of approval to sell its products, she got on the phone.

“Before we got all our paperwork, we were giving away a lot of cheese to friends and family and they kept asking ‘when can we buy it?’,” says Kirsty.

“Mum was so great. She just rang everybody, ‘do you want to buy any cheese – how much do you want?’ So it was just by luck we had sort-of done our marketing and we already had a market.”

In that first official year, Kirsty made 300kg of halloumi, feta and pecorino in her DIY cheesemaking factory. In 2016, it was 450kg. In the 2017-2018 season she’s expecting to produce 800kg of cheese and customers can’t wait. The feta Kirsty made on her first day of cheesemaking for 2017 was sold before she’d cut the curd.

“We supply the most fantastic cheese shop down in Featherston called C’est Cheese, it’s like an Aladdin’s cave, and the cheese I’ve made today has got their name on it. (Owner Paul Broughton) has been asking me for more for a couple of months, so that’s going straight down there.”

.

Kirsty’s artisan cheesemaking journey began when her partner Dave Chapman gifted her a cheese kit in 2011. She started using local organic cow’s milk and found the process so enjoyable, she took a few courses to learn more.

“Our friends and family loved the cheese I was making and I found myself making more and more of it.”

In 2012 the couple visited Dave’s daughter Cara, who was living in Italy.

“While we were there we did some wwoofing (working in exchange for food and accommodation) on a small dairy farm. I learned how to milk sheep and goats by hand, while Dave did some building, scything, and even shearing with good old-fashioned clippers.”

The family who owned the farm made their own raw milk cheese to a traditional recipe and it was inspiring.

“This got us both thinking more about what we could do when we returned home.”

The couple lives in the small rural community of Woodville on a block Dave bought back in 1995. He built a house and ran sheep, cows, a large flock of chickens and some ducks. When he met Kirsty, the collection of animals quickly grew to include alpacas, cats, and a dog.

“And anything else that turned up!” jokes Kirsty.

Cheese ready for sale.

Their lifestyle business, inspired by that trip to Italy, was designed to be enough work for just the two of them, and they do it all: farm the sheep, milk them, and make and sell the cheese.

But before they could get anything underway, they sat down to have a read through the very imposing rule book on cheese manufacturing in NZ.

“There were about 500 pages of Ministry of Primary Industries (MPI) regulations to go through, and the cost structure was all set up for big companies,” says Kirsty. “It was a mountain of material to read through but I knew that if I didn’t do it then it would never get done, so I just got on with it.”

While Kirsty tackled the paperwork, Dave was busy designing and building what is now their Mark 1 milking platform and converting an old stable into a modern cheesemaking room that met the strict standards and regulations.

It was 2015 by the time they finally conquered the paperwork, wrote up their Risk Management Plan, and could begin making cheese to sell. “In our first season, two-thirds of the cheese I made, we gave away,” says Kirsty. “But we realised our idea was workable, so we decided to buy some Poll Dorset ewes and some East Friesian rams to build up our milking flock.”

Dave hand-picks which rams go over which ewes in the flock which totals around 100 animals, with 50-60 in milk.

The couple now sells their cheeses online, at the local farmer’s market, and through a few cheese stores. When Kirsty is not busy making cheese, she runs workshops teaching others how to do it. The courses, which she tries to run once a month, have proven popular and fill up fast.

“One course, we did a farmhouse-type cheese… and one of the husband and wife teams, when they got home they lovingly washed it in whiskey, I don’t know for how long, so I’m waiting to get an invite to taste that. I saw it a couple of weeks later and it smelt absolutely beautiful. It’s quite fun to play around like that.”

Wild Bush Cheese has now expanded to keep up with demand. As sales grew, Kirsty and Dave realised they needed more land and a larger milking shed. In 2016 they purchased another block not far from where they live. It has increased their grazing land to 7ha in total, and given them room to build a much-needed Mark 2 milking shed.

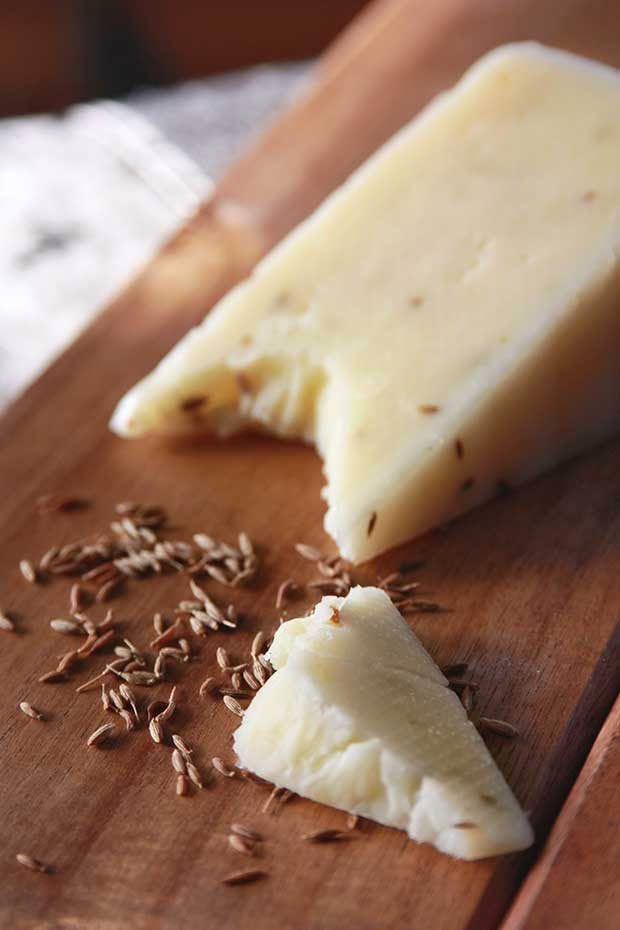

Sheep milk has more fat and protein than cow’s milk, perfect for cheesemakers like Kirsty. This is her traditional feta, flavoured with chilli flakes.

“We kept the cheese factory here, but we do our milking at our new site which is a lot bigger,” says Kirsty. Their farm is small by local standards, where a typical property has thousands of stock, but the community has been very supportive.

“Just the whole idea of sheep milk cheese was our biggest hurdle,” says Kirsty. “In places like Dannevirke, people that have farmed sheep and beef for years, they don’t drink sheep milk and they don’t want to eat sheep milk cheese. The older farmers, the men, are the hardest to sell to, so that was our biggest thing when we first started.

“But now, people say ‘oh! Sheep milk, yes, I want to try that!’

The cheeses are vacuum-packed for easy storage and ageing.

“I think we were at exactly the right time when the tide was changing. I’ve kept our range very minimal, I only do feta, halloumi, and the pecorino and that’s enough. People wonder why we do feta, but it sells because people like it.

“To be honest, it’s the most simple cheese for me to do too – it’s kind of my bread and butter cheese.”

LESSONS FROM KIRSTY AND DAVE’S CHEESE FACTORY PROJECT

Cumin seeds lend a warm, spicy flavour to the pecorino.

No amount of life experience could have prepared Kirsty and Dave for the bureaucracy of setting up a cheese factory.

“The actual cost of everything is just so much higher than what I had estimated,” says Kirsty. “And it can be frustrating dealing with MPI (the Ministry of Primary Industries) – that’s our biggest hassle.

“Because we’ve done it all ourselves – we’ve written our RMP, we’ve built everything, we’ve bred our sheep – we’ve had some questions, and we have tried to get in touch with MPI to ask these questions. In one case, Dave was sent from the original person to seven other people before he ended up back at the person he first started with, and they still couldn’t answer his question.”

The MPI rules are written to apply to large-scale factories. Kirsty quickly figured out it was best to go from there and scale down.

“It’s one of the things I’m really, really pleased with. I made it a mini factory rather than a flash commercial kitchen, so that means things like I can wash down the walls and its got a sloping floor.”

The sloping floor was meant to direct water into a drain at the lowest point. Getting the concrete poured and contoured was the only part of the entire project that Kirsty and Dave didn’t do themselves because they felt it warranted a professional approach. Unfortunately, the floor doesn’t slope to the drain.

“That’s one of the things I’d do differently! I’d not pay them before I checked it did slope to the drain.”

The wording of the regulations was also tricky. Kirsty used to be a teacher and she says that experience was useful when it came to the detail of official ‘speak’.

“When I read the regulations the first time, I looked at them as what you had to do and that was anything that said ‘must’. But there was a lot that said ‘should’ and initially I was trying to do all the things that you ‘should’ do as well. But then I realised ‘no, I don’t have to do all of these, I’ll do the ones I can’. It would be nice to do them all, but as long as I can show I’m meeting the requirements and I can do it some other way that’s less technological or cheaper to do, then I’m going to do that.”

One example is ventilation. The rules describe and point you towards an expensive air conditioning system.

“But it’s way over the top for what we do. We’ve only got 20 square metres or so, it’s tiny and it’s usually one person working in it. There’s windows on one side and a ranch slider on the other with screens. That’s my ventilation system – I open a window!”

The factory was built on the footprint of an old stable and the couple has made good use of the limited space. The main room can fit six to seven people in it if required. There’s also a small foyer where Kirsty changes into her cheesemaking clothes, sanitises her hands and puts on sanitised footwear.

Their small budget meant some creative problem solving for some of the more expensive aspects of the construction. The concrete floor had to be easy to keep clean, which meant it needed to be sealed with a 2-pot epoxy paint. It was an eye-watering experience says Kirsty.

“We got a guy to do a quote and it was $10,000 – he was quite apologetic about it and we said we couldn’t afford that. Then we did some research and found a guy in Hawkes Bay who had the 2-pot epoxy and we got it for $1500 and did it ourselves.”

The choice of cladding on the walls was also a happy, budget-friendly accident.

“We were going to use the stuff that you put in bathrooms – Seratone – but then we were talking to the guy who built our milking platform for us. He’s an engineer and he also builds horse floats and he said ‘there’s this aluminum sheet we use in the horse floats, you should use that’.

“It’s powder-coated white on one side and it comes in lengths of 3m, you can just wipe it down and everything comes off easily.”

MEET THE SHEEP

When you are milking any animal, it’s important to keep them as healthy as possible. While their property isn’t organic, Kirsty and Dave believe it is important to be good managers of their land and one positive is it means they can minimise their use of chemicals like drench. Drench products have withholding periods and you can’t use the milk in that time, which means a ewe is out of action for weeks.

The flock started with just three ewes, and now includes East Friesian and Poll Dorset breeds.

“One of the main things we do is try not to be overstocked so we don’t have so much pressure on the pasture, and we do rotate (grazing),” says Kirsty.

“We try to keep them in as good a condition as possible, so even if they do have a bit of a worm burden, it’s not affecting them.

“Sheep aren’t as bad as goats – goats are terrible for worms – and it tends to be the young sheep that have problems. In our flock, there’s 10 replacements a year and if they need to come out because we’ve had to drench them then they can. Once they’re two, three, four years old – and we’ve got some five and six years old – they don’t seem to get too bothered by the worms.

“And it’s not great for them, to drench all the time – I mean, it is a poison.”

Dave is the one who loves the challenge of breeding and jokingly calls himself a ‘sheep genealogist’. He is in charge of the animal husbandry, deciding which ram will get together with a particular ewe.

“I love the breeding side of the business so I spend a lot of time out in the paddocks working with the sheep,” says Dave. “Some of our white sheep are prone to sunburnt ears in the summer, so we have started experimenting with black sheep to try and overcome this. We’ve now also got East Friesian and crossed East Friesian-Poll Dorset sheep.”

He’s also in charge of nutrition, sowing red clover into the pasture on their home farm and their new block, and fertilising the soil. This season they’ve got an added pasture option, grazing the local race track, where their hoggets are growing fast on protein-rich plantain.

WHERE TO BUY WILD BUSH CHEESE

Markets

Wairarapa Farmers’ Market Saturdays, 9am-1pm

Hokowhitu Village Market, Palmerston North, third Sunday of each month, 9am-1pm

In-store

C’est Cheese

19 Fitzherbert St, Featherston

Organic Living

Broadway Shopping Centre, Palmerston North

Culinary Vista

74 Vogel St, Woodville

Eclectic Country, SH1, Sanson

The Silky Oak Chocolate Co

1131 Links Rd, Napier

Love this story? Subscribe now!

This article first appeared in NZ Lifestyle Block Magazine.

This article first appeared in NZ Lifestyle Block Magazine.