Organic and sustainable Clean Earth Soap from Golden Bay

Working from home is the ultimate dream for many people but setting up a business can seem so daunting and risky that it remains a fantasy.

Kerryn and Phill both work part-time off-block, but when a friend told them about the soap-making business she was selling, they could see a great opportunity and felt it was a good home business that they could expand while they built their house.

Kerryn has always enjoyed craft making, and she was wondering what she could turn into a business when the opportunity arose. While her knowledge of soap-making was limited, she had already studied essential oils through a correspondence course which proved useful for what has turned out to be Clean Earth Soap.

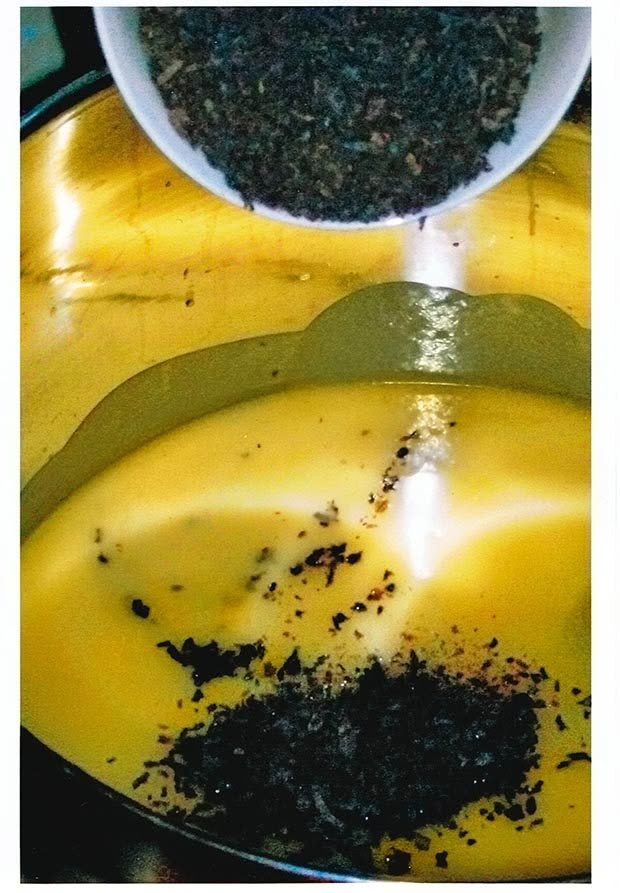

Oils are often solid in soap-making so must be melted and mixed together.

Golden Bay is not an easy place to make a living. Its isolation and small population means that people have to be innovative and creative at earning those precious dollars. The internet has helped enormously where business owners previously struggled to reach distant markets.

Kerryn liked the idea of selling an environmentally friendly product with well-sourced ingredients. Her soap is 50% olive oil which she finds hard to source in New Zealand, but she feels this will improve as more olives are grown. Soap-making doesn’t require table grade olive oil as a second pressing of lower grade oil works well.

The other ingredients are certified organic coconut oil from the Philippines and certified organic palm oil from Columbia. Kerryn stresses that this type of palm oil is from a sustainable, well-managed source, completely different from the palm oil that receives bad press when indigenous forests are felled for plantations. Buying from an organic source encourages sustainable management and helps promote organic growing.

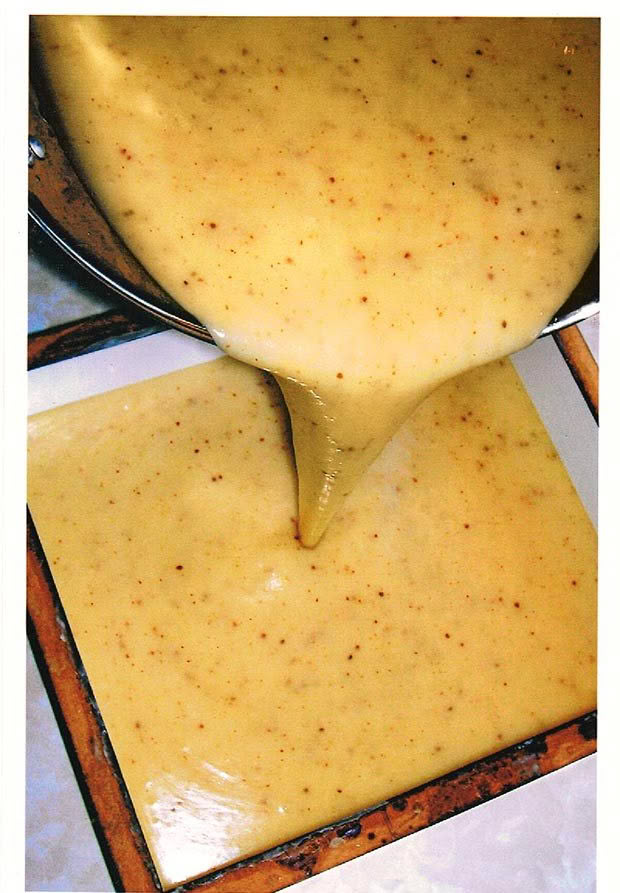

Pouring the hot soap mix into moulds.

To make the soap, Kerryn gently heats and melts the coconut and palm oil to a liquid and adds them to the already liquid olive oil. A lye solution is then used to saponify the oils.

Lye is caustic and tricky to make which is why Kerryn prefers to buy it. The last ingredients to add to the mix are the essential oils which give the soaps their appealing aromas.

The mix is poured into moulds and left for 24 hours before being taken out and cut. Kerryn’s soap cutter comes from Canada where hand-made soap is popular, and every batch she makes is cut into 220 perfectly-even pieces. The soap is then cured – a process which takes six weeks – then the soap is ready to be packaged and sold.

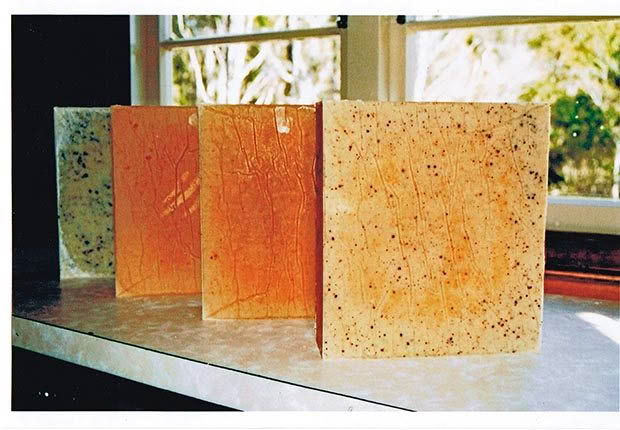

The finished product, cut into individual pieces.

When they bought the business, it was producing four different scented soaps but Kerryn and Phill have now increased it to 10, and they believe there is potential to expand the range further. They have also been pleased with the response to a new dog soap and shampoo, and gift options of scented soaps wrapped in coloured felt.

Kerryn sells the soap on their website, and to shops in the North and South Islands. She has a market stall in Takaka and also travels to other craft markets in the summer months. She says she enjoys the interaction with her regular customers, and there is great local support and a number of repeat internet customers. Unlike selling food products, soap keeps, so there is no wastage, but fortunately there has been good demand for it.

The soap is made in slabs which are then cut to size.

The best part is the satisfaction of selling a product from a cottage industry that is appreciated by customers, and doesn’t harm the environment, says Kerryn.

“We live in such an amazing country. It’s about looking after it.”

Love this story? Subscribe now!

This article first appeared in NZ Lifestyle Block Magazine.

This article first appeared in NZ Lifestyle Block Magazine.